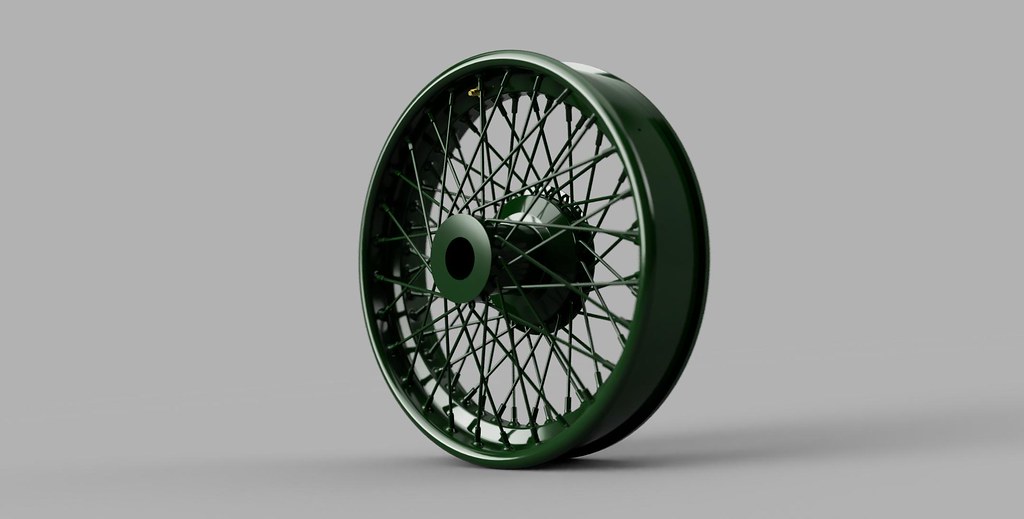

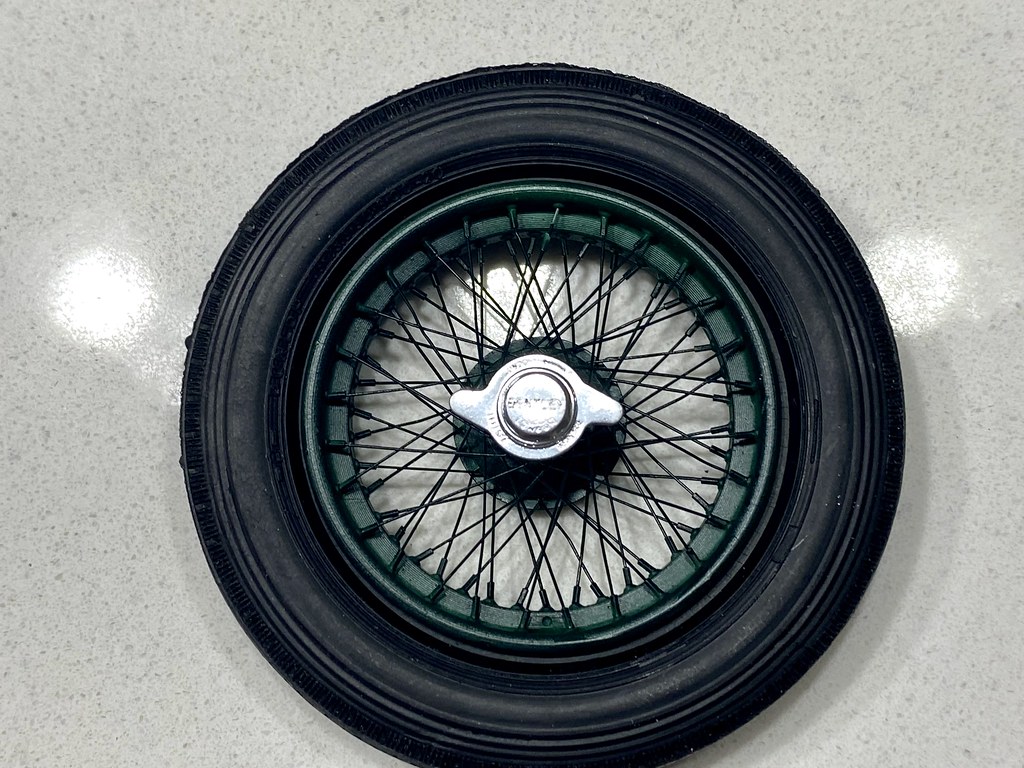

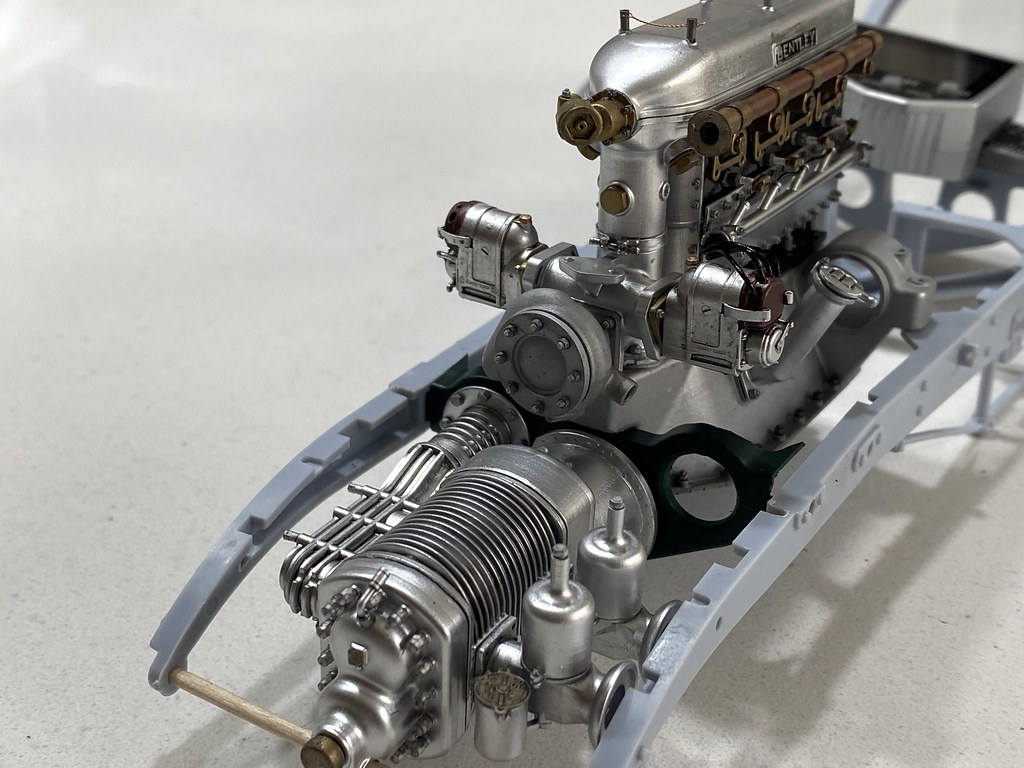

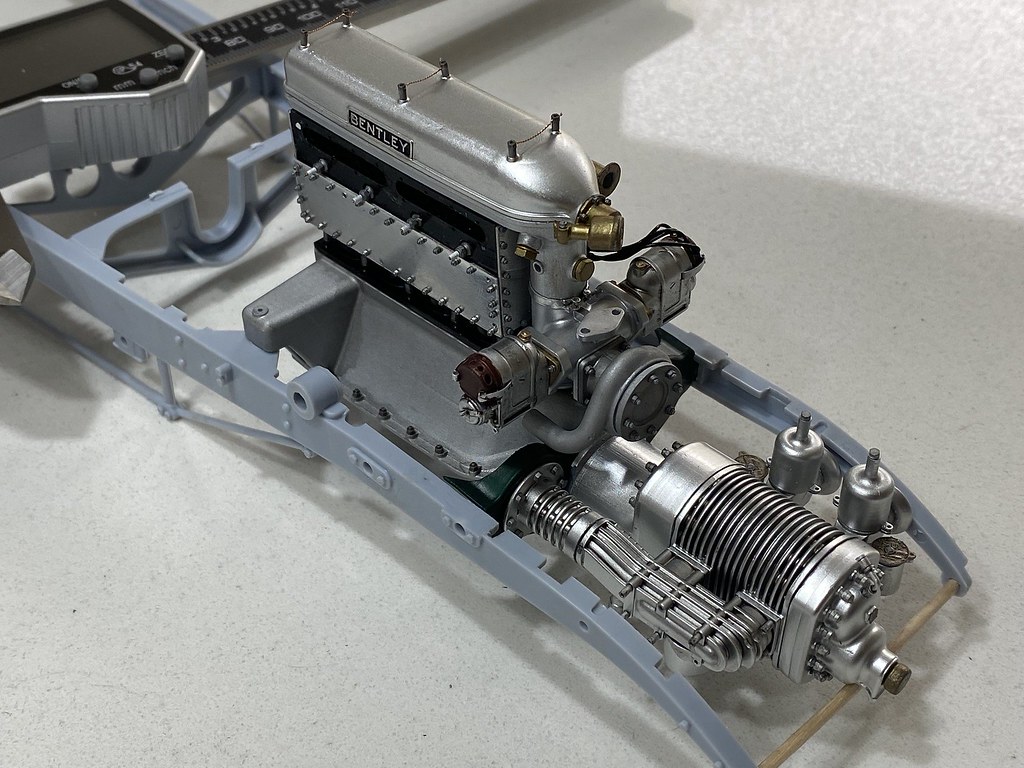

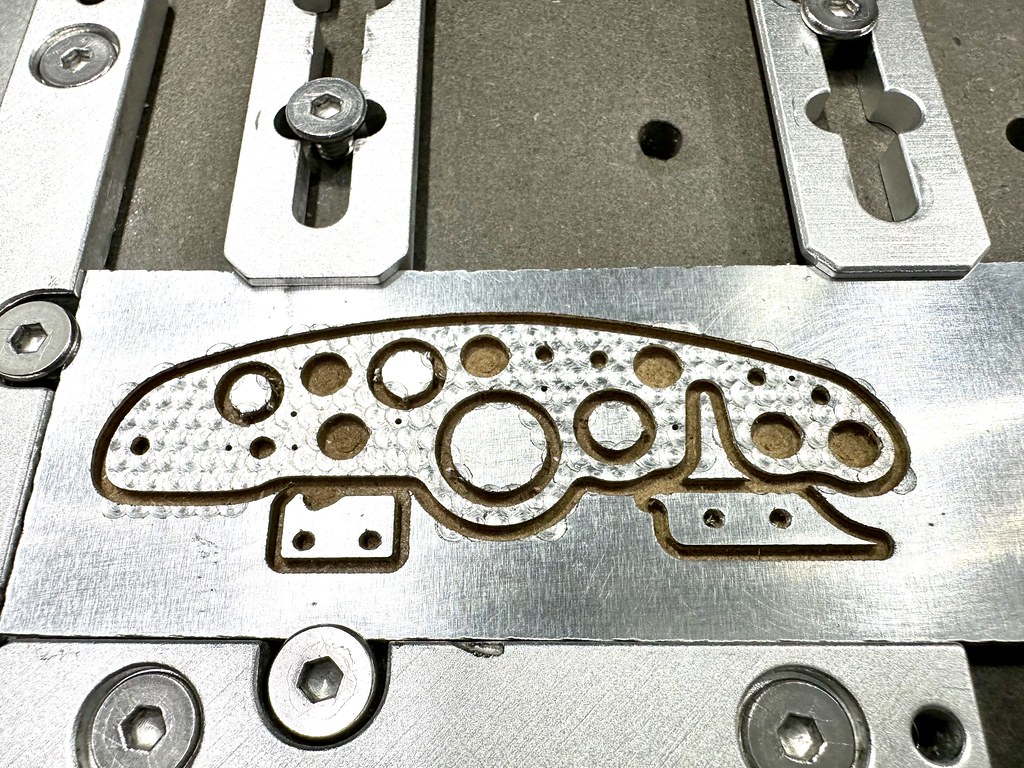

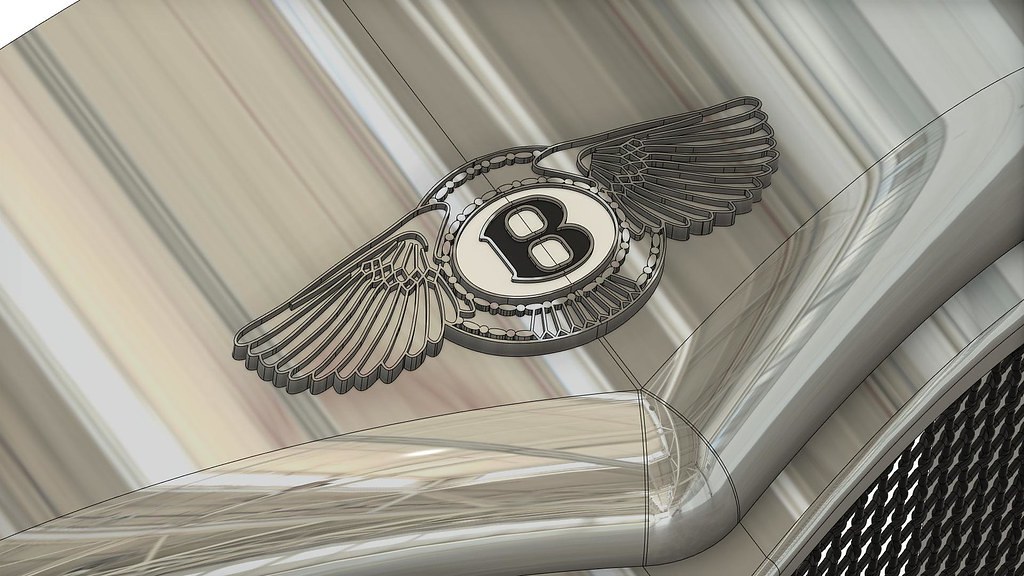

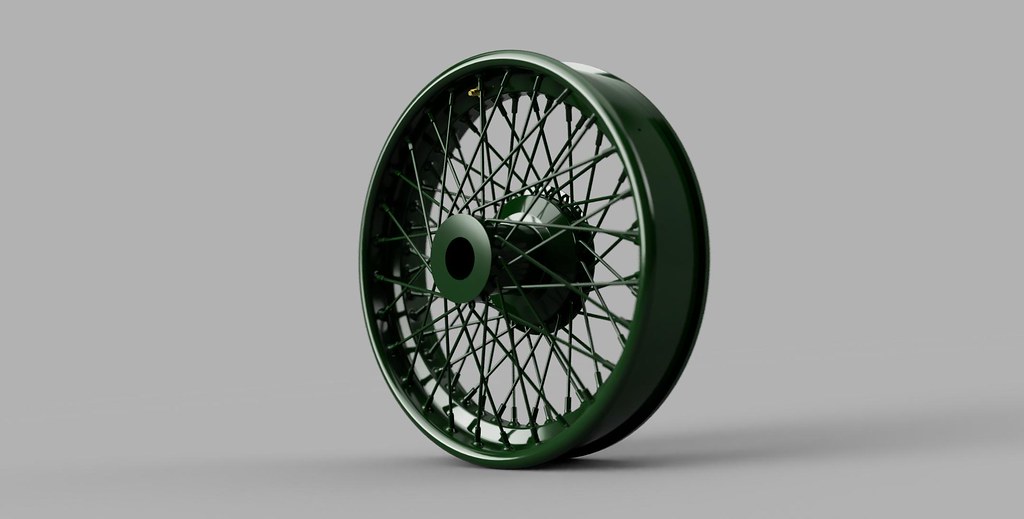

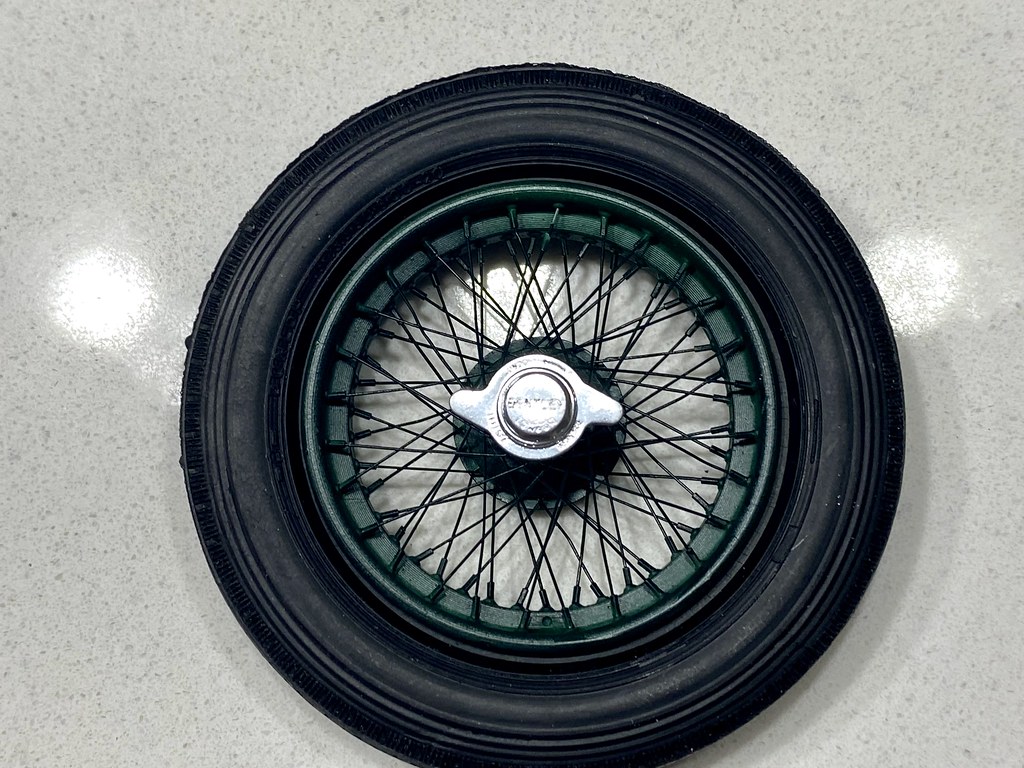

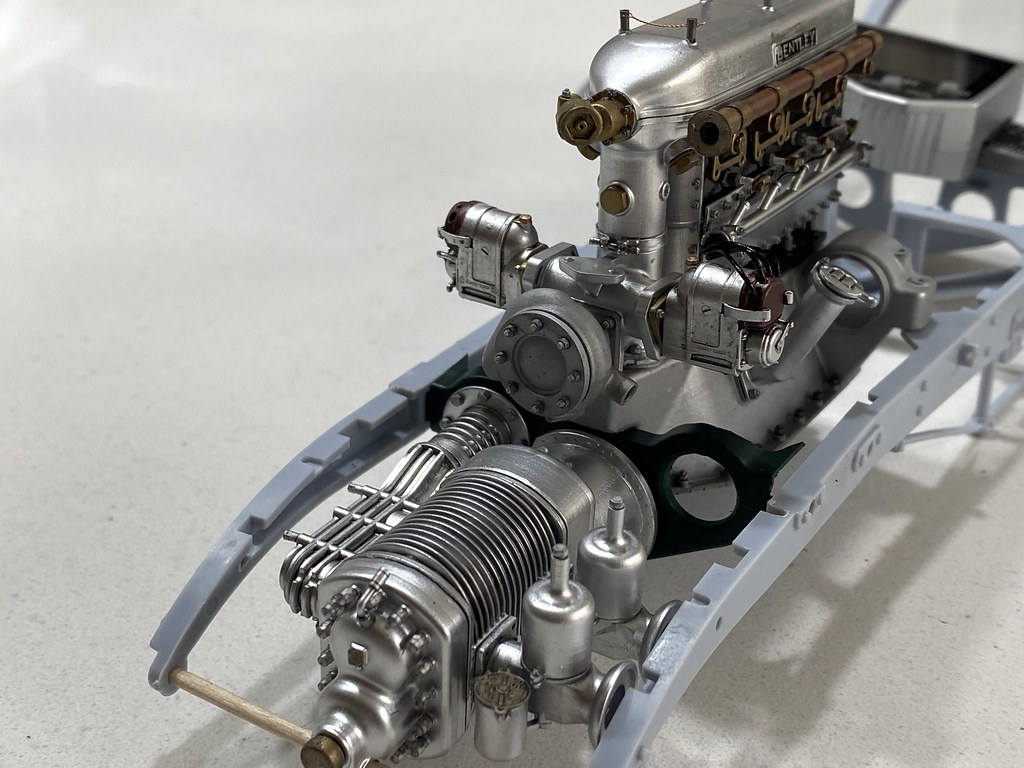

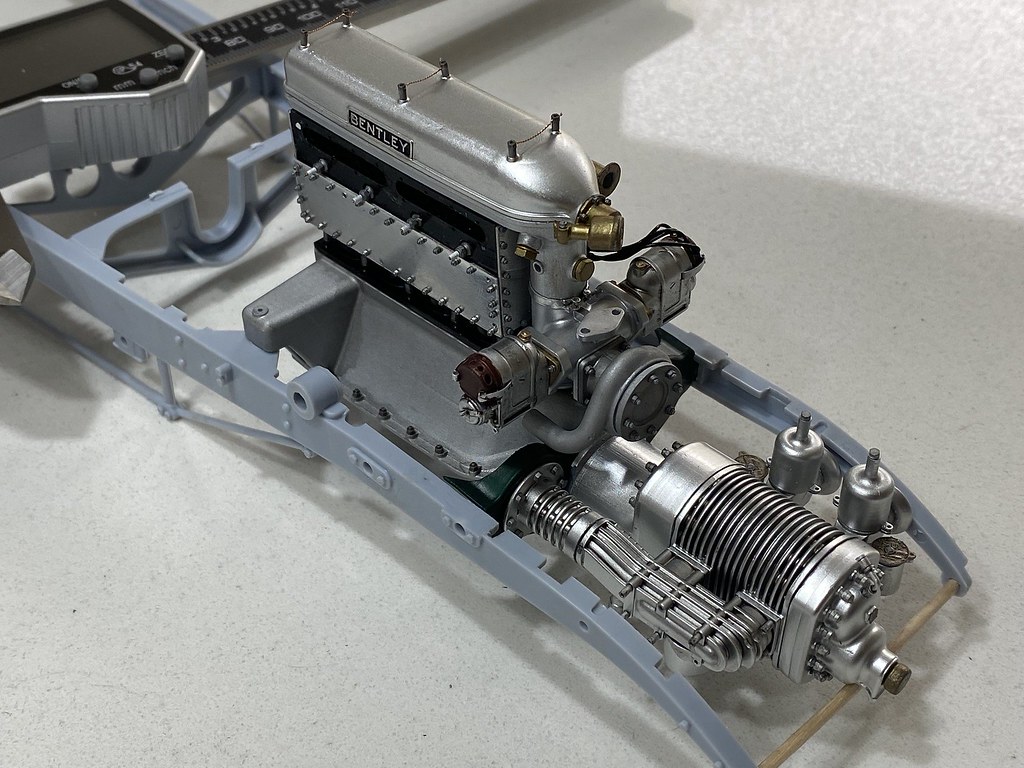

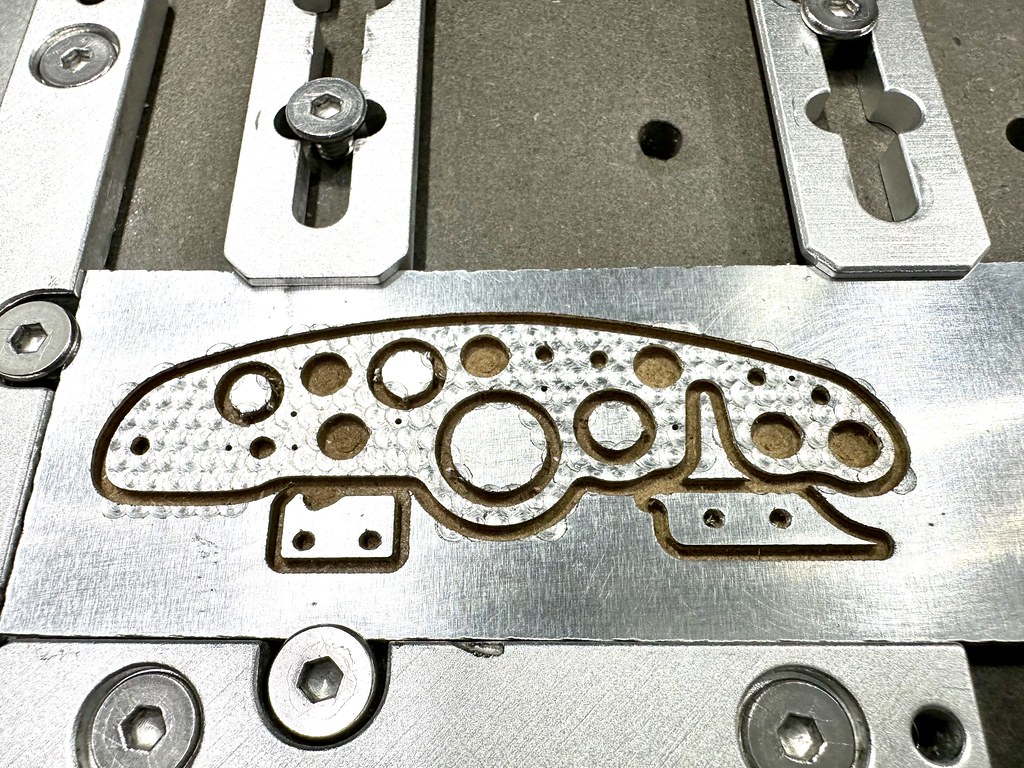

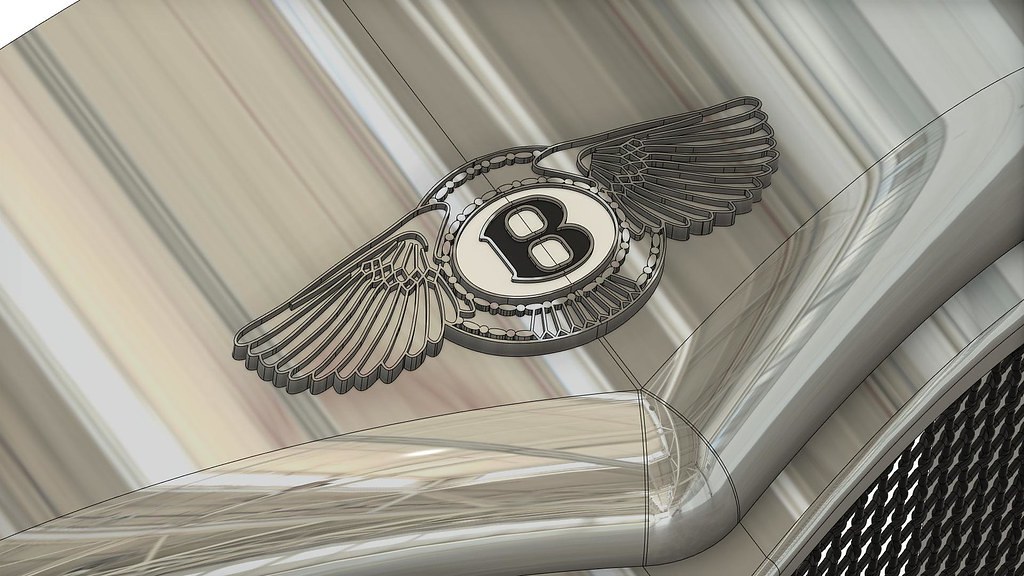

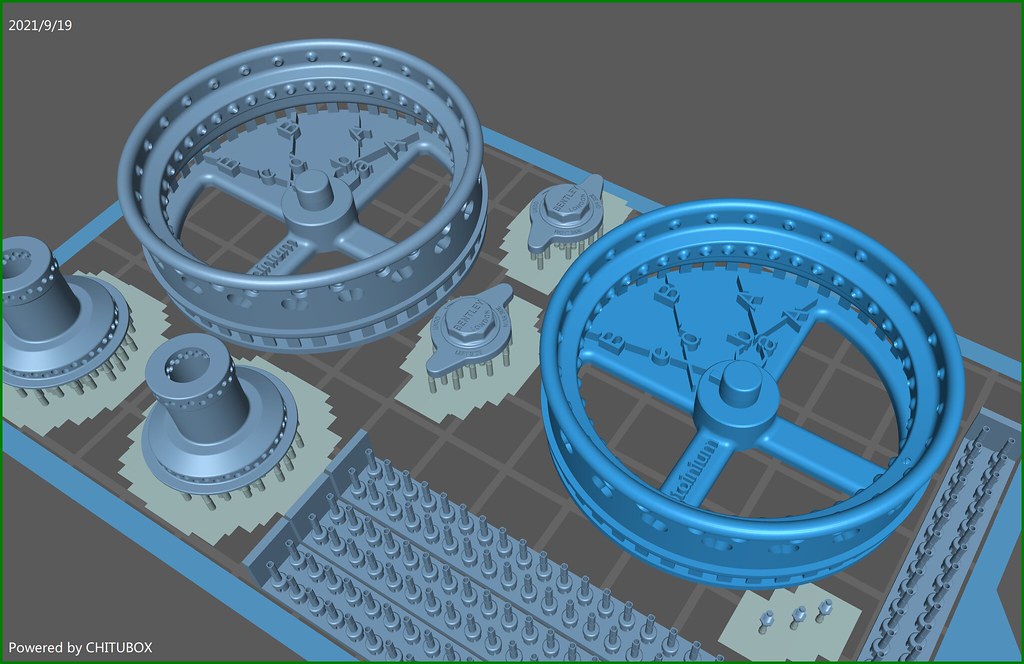

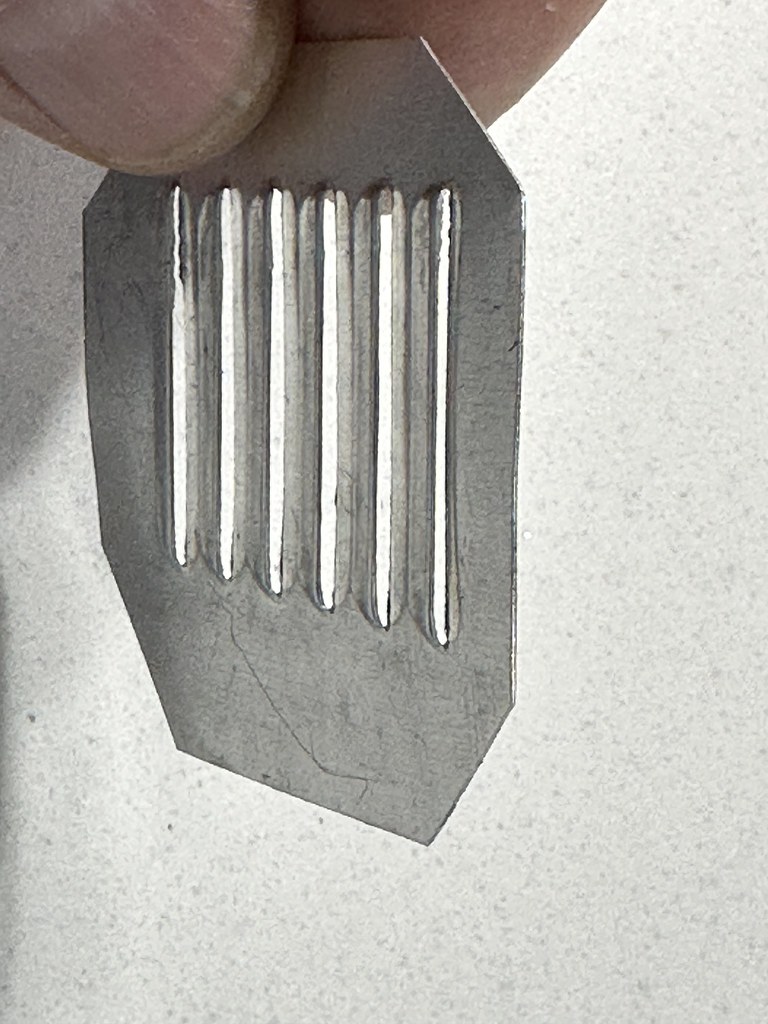

Hi everyone, I’m new to the forum and would like to share some of the CAD/CAM work I have been doing to try and make something of the ancient Airfix kit Over the last year or so.

some are CAD drawings I’ve done, renders of the drawings and finally actual real-world parts 3D printed and CNC Machined, hopefully you can tell which is which!

thanks for looking and the warm welcome.

Nick

some are CAD drawings I’ve done, renders of the drawings and finally actual real-world parts 3D printed and CNC Machined, hopefully you can tell which is which!

thanks for looking and the warm welcome.

Nick

Comment