Science fiction not many years ago. Astounding result.

The venerable Bentley Blower in 1/12th

Collapse

X

-

-

Its testing my faith in physics, it's perfectly vertical so the only stress on it during printing is directly upward and its a tiny surface area. It's only your brain telling you its a big curved sheet of stuff - it isn't

Youre probably right though after all that We'll know about tea time.

We'll know about tea time.

Comment

-

-

-

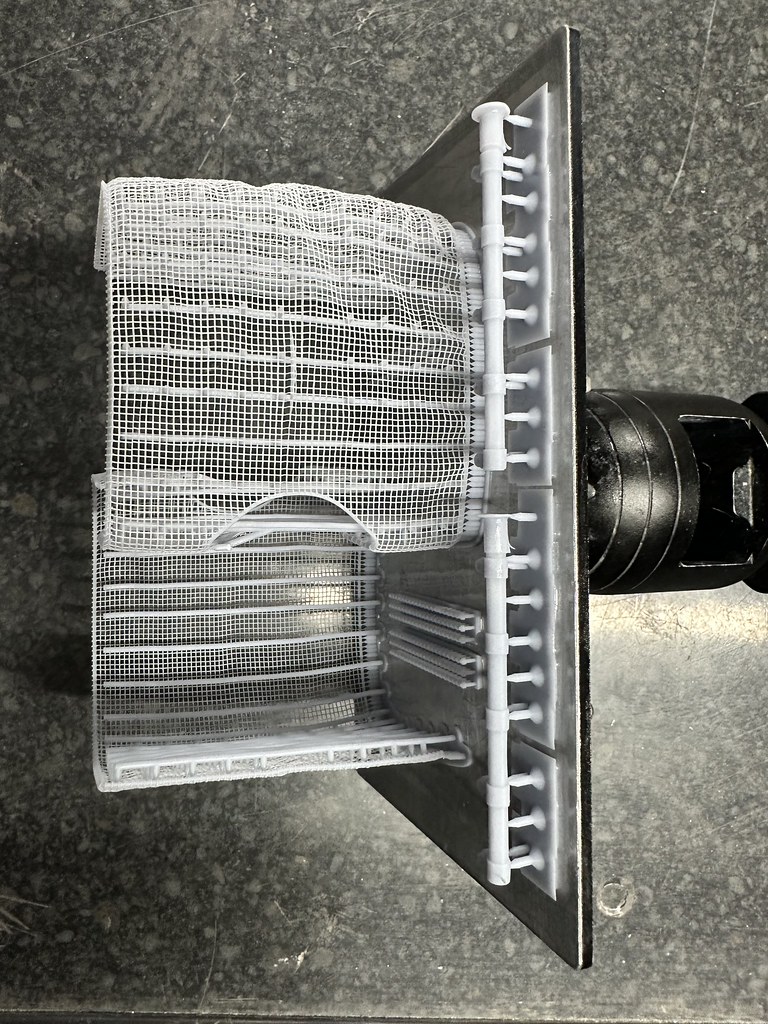

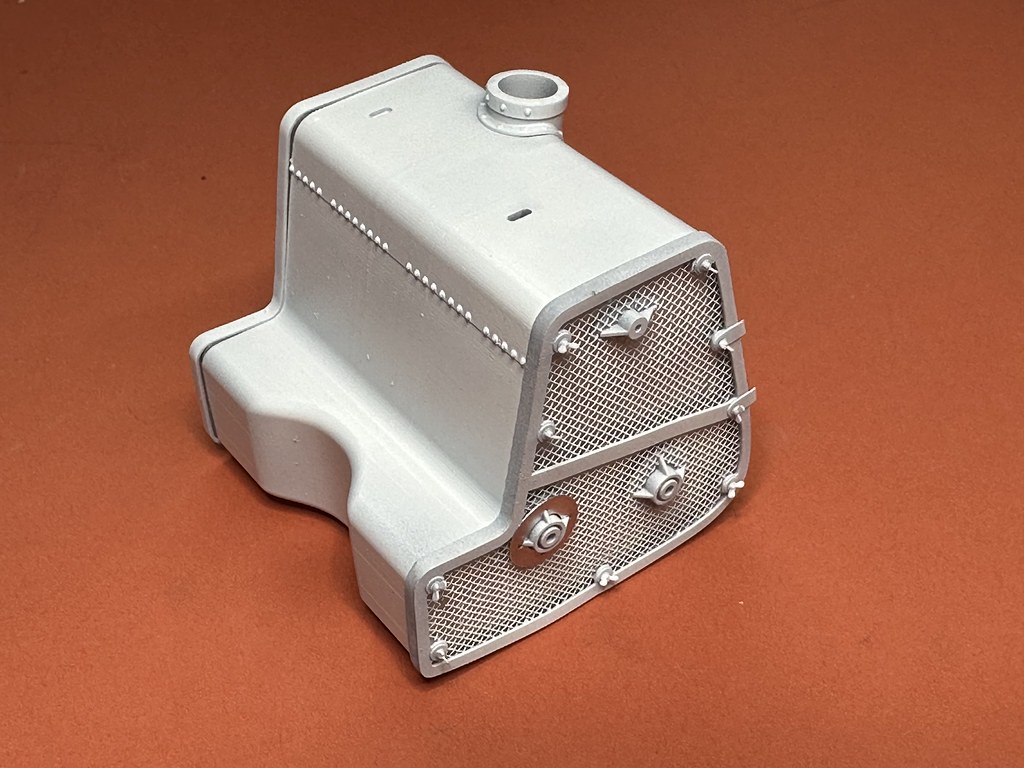

It was easy in the end.

Ish.

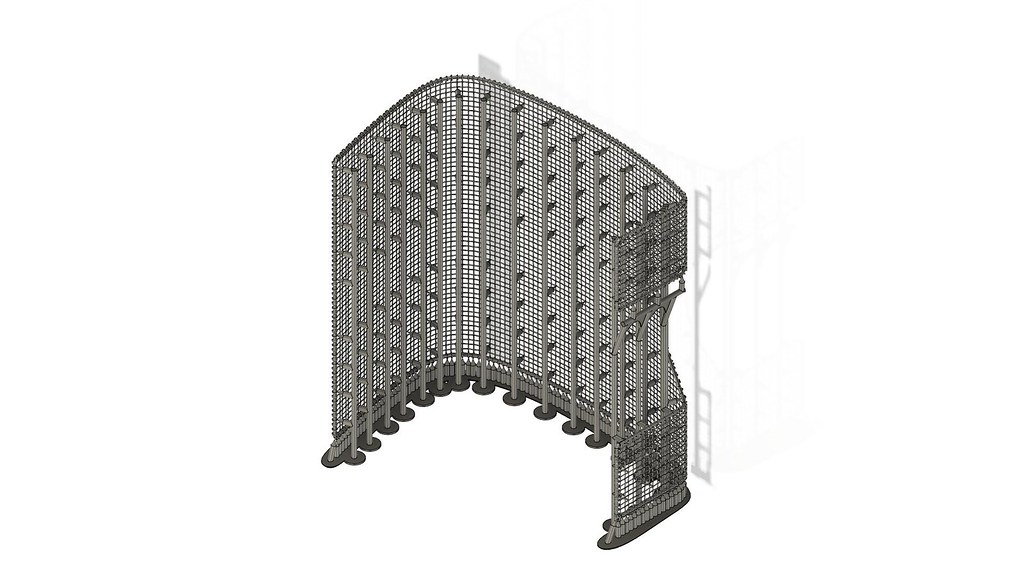

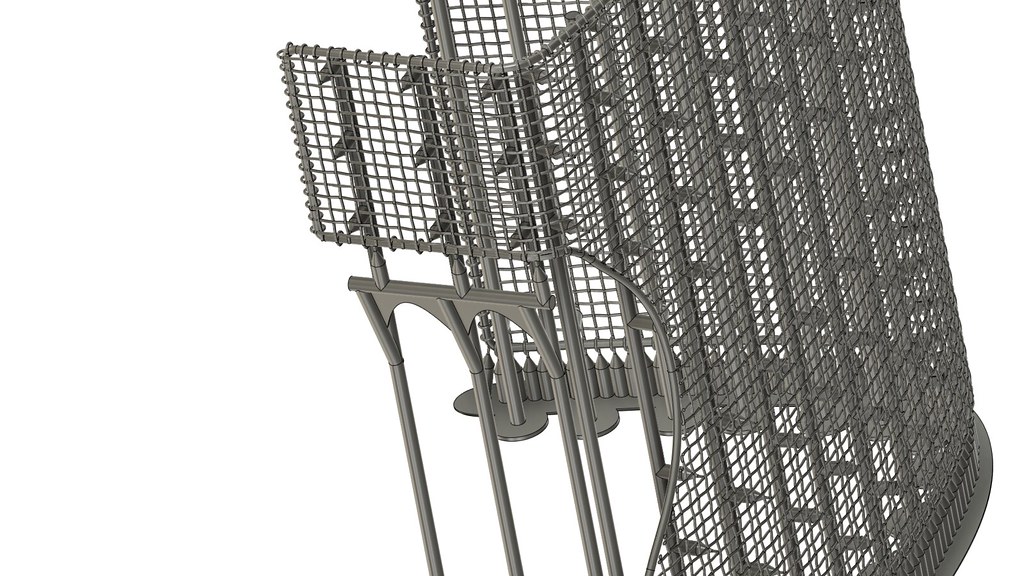

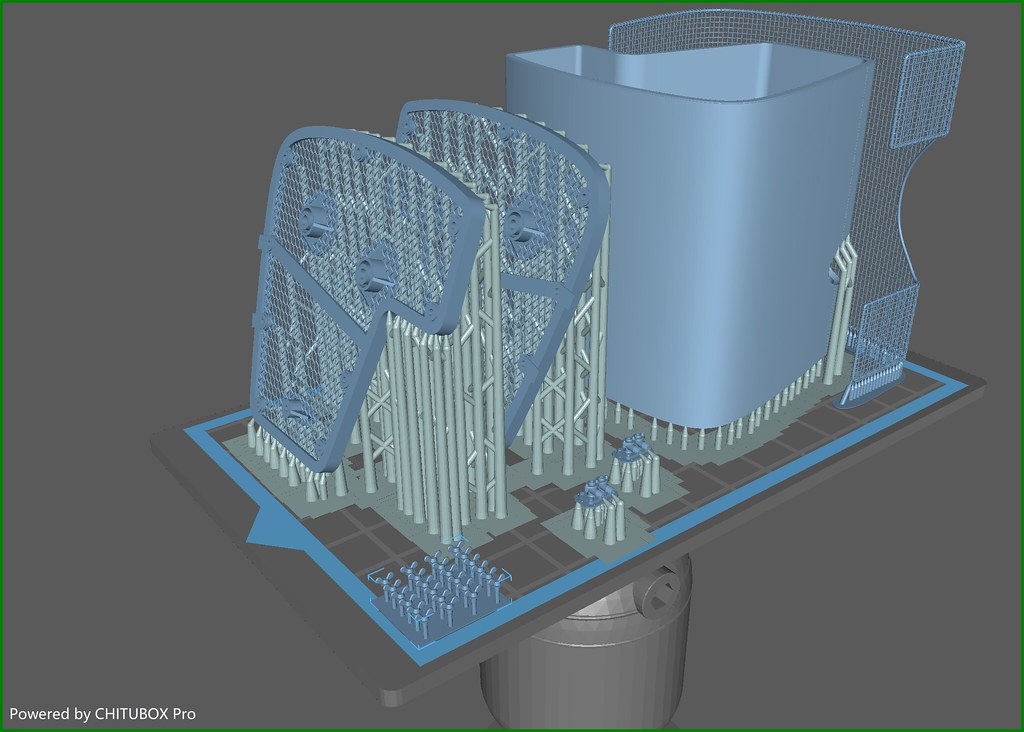

This was always going to be too fine to use slicer-generated supports so I ended up designing and drawing these in fusion 360.

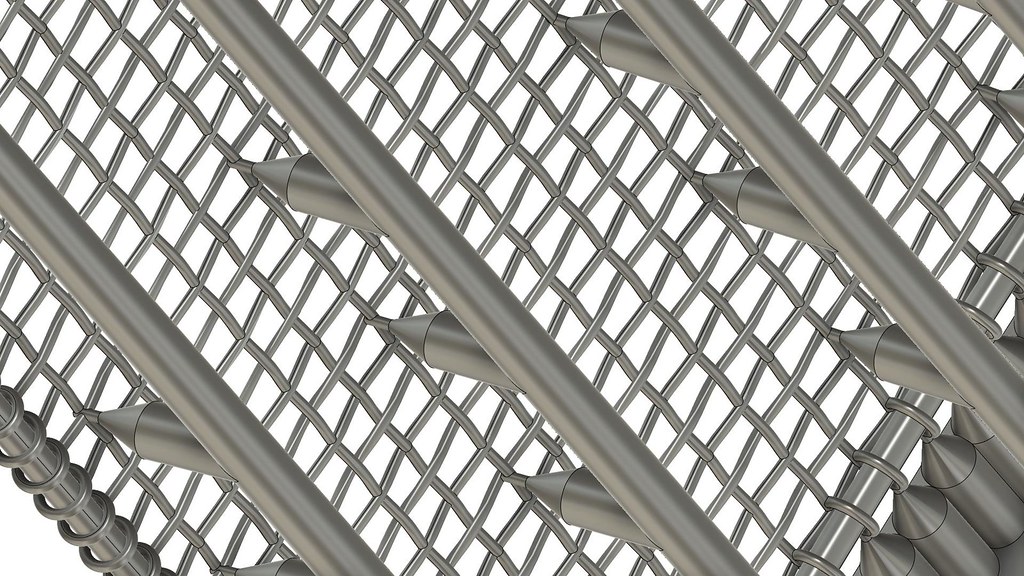

Version 1 failed because of the horizontal wires. Every time you get to the centre of one, that’s a relatively large surface putting a high load on the much smaller vertical cross section wires preceding it and eventually it just pulls free and fails.

I also overlooked the cut out for the differential so this needed it’s own supports too

I seem to have this Victorian iron works/steampunk thing going on here for some reason?

Anyway, it worked, you can also see the baggyness I was talking about earlier, this goes away as it dries/cures

NickComment

-

Comment

-

Ingenious! Great problem solving, great result, love it!

What size is the mesh and how thin is the 'wire'?Comment

-

Fully agree, I am old school with scratchbuilding etc. But sometimes I look towards this new technology and wish I had the experience to use it and save me time. And to be honest I still keep looking, and still keep control of my credit card because I know once off the leash I would be gone....WELL Guys thinkin this through i aggree with Steve an i'll proberly get shot for this from you guys esp the guys who have bad aritise in their hands but yes this cad thing is great but here we go i dont think its modeling as such as the machine is doin all the building an not the moddeler like i like to scratchbuild the part that i need an not just let the machine do it Aaaaaaccchhh there ive said it now so all feel free to have your sayComment

-

Had a look and play with the scroll/rotate. I see you use Fusion, do you reccomend it for beginners - because that is where most of us are at the moment, we look, but the tech puts us off. I tried Gimp, got the book, downloaded the program and watched the videos, but still fell flat. And I should know better after using Flash MX etc during my Graphic Design degree course.If anyone would like to see it (after all that! :smiling3: ), here is the CAD drawing I'm still working on for the Bentley Engine :- Bentley Blower CADComment

-

YES I ALSO fully aggree Mike an wish i could understand this cad but its way over my head an yes the card would be seriouly hit with the cost of buyin one of these an Nick is this cad stuff very heavy at all or about the same as 1mm plasticard thickness wheight ?Fully agree, I am old school with scratchbuilding etc. But sometimes I look towards this new technology and wish I had the experience to use it and save me time. And to be honest I still keep looking, and still keep control of my credit card because I know once off the leash I would be gone....

chrisbComment

Comment